Kopin has just issued a press release that states their intention to enter the OLED microdisplay market, offering panels that will serve augmented and virtual reality applications. At CES 2017, they will announce more detail on the first panel and demonstrate it in novel optical solutions as well. I will get a sneak peak at these devices before CES, but you will have to wait until January 2017 before I can say more.

In the meantime, I can talk about Kopin’s path to get to this point and their new business model. To learn more, I had a conversation with Kopin CEO John Fan.

Readers may recall that Kopin developed their microdisplay business based upon a lift-off process for transmissive LCDs they call CyberDisplays. These remain popular in various types of consumer, military and industrial grade near-to-eye viewers and head-mounted displays.

Several years ago, Kopin purchased Forth Dimension Displays, the Scottish LCOS panel maker whose microdisplays are used primarily in military and high performance commercial near-to-eye and head-mounted applications.

Now, Kopin has added OLED to its repertoire of microdisplay technologies. According to Fan, “Kopin is pioneering a new business model for OLED fabrication which we think is the future for expanding availability of OLED microdisplay devices.”

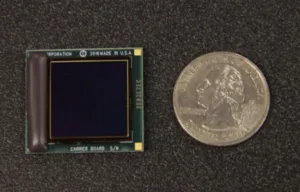

After two years of development, Kopin is now ready to start showing its new OLED-on-Silicon microdisplays. Such a device consists of two key elements: the silicon backplane that contains circuitry to drive the OLED pixels, and the OLED emissive frontplane layer. What is unique about Kopin’s business model is that both of these operations are outsourced to dedicated foundries. All of the design expertise resides within Kopin, but all of the capital investments and infrastructure are external, with manufacturing expertise on both sides. It is the first fully fabless OLED microdisplay business model.

If this sounds familiar, it sort of is. Many LCoS microdisplay providers do the same thing. The silicon backplane goes to a silicon foundry such as TSMC or UMC and the liquid crystal frontplane fab goes to a foundry such as Hana.

But not all LCoS or OLED microdisplay panel providers follow this model. While all outsource the silicon backplane, many keep the LC or OLED fabrication in-house. Kopin does this with its LCoS panels and eMagin follows this model for its OLED microdisplays.

There are advantages to this, but there are also disadvantages. The big reason Kopin has gone all fabless is to be able to respond to a big increase in demand for OLED microdisplays should the VR/AR/MR market take off. “Capital investment in an OLED foundry is not cheap and we think this is the best way to leverage the investments of others to be ready for the market,” stated Fan.

While Fan says the firm will reveal more about their its panels at CES, he did note that, over the last two years, they have developed considerable IP around the design of the backplane and manufacturing process steps to make it compatible with OLED frontplane fabrication. “We have 10 patents filed with some already granted,” said Fan. “Some are related to the planarization of the silicon and the anode deposition process, which is done at the silicon foundry, and some are related to the design of the pixel circuitry and drive electronics. Since this is silicon, all of this circuitry is on the panel so there are no external driver chips needed. Overall, our OLED microdisplay device will offer high resolution, fast refresh rates, very low power and latency and great performance.”

Kopin has secured deals with silicon and OLED foundries to create the frontplane on these silicon backplane substrates. But what is nice about the model is that it can be extended to other silicon and OLED factories. “Such a flexible model is why we believe this is the right way to create the lowest cost OLED microdisplays,” said Fan. The names of their silicon and OLED foundries have not been revealed, however.

Fan then noted that by having all the design expertise in-house, customized designed can be turned around quite quickly, if needed.

Kopin also sells optical modules that include its panels. We should see some of these at CES featuring the new OLED microdisplay panels and learn more about their performance and potential use cases. – CC

Kopin contributed to the editorial cost of creating this content which was independently written and edited.