As is often the case, one of the most interesting things that I saw at the SID was not on the show floor, but in a dimly-lit suite in a hotel near the event, where Ignis Innovations was showing its wares.

Ignis is a Canadian developer of backplane and compensation technologies that we have been reporting on since SID in 2004, when it was working alongside Novaled (now owned by Samsung).

(Backgrounder: While TFT LCDs use very simple single transistor circuits because they are voltage driven, OLEDs are current driven, so need more complex transistor configurations. We have heard that up to 7 transistors per pixel have been used in some designs – that means 174 million transistors for an UltraHD panel – and nearly 700 million for an 8K panel!)

Ignis has a range of technologies that it has developed that may help OLED TV get further along by helping panel makers to fix some of the problems that they face in bringing OLED TVs (especially TVs, although the technology is useful in all sizes). At the SID, the company was showing how its transistor designs could be used to reduce the number of transistors to just three per subpixel, and “move complexity from the backplane to the driver”.

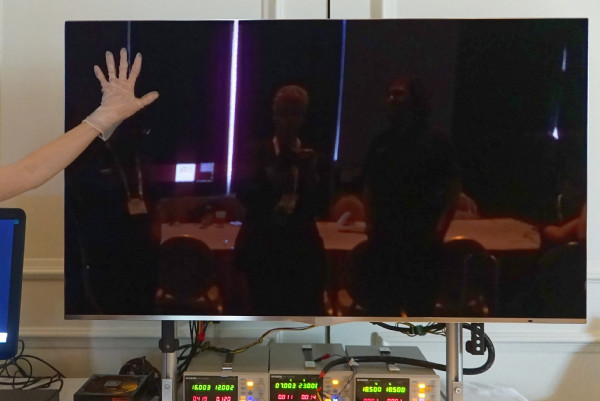

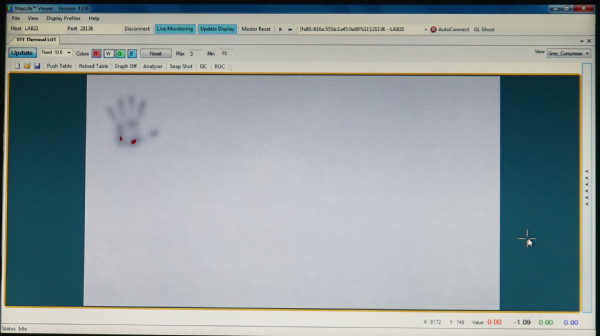

OLED materials are extremely sensitive to environmental factors such as oxygen and water, but they are also very sensitive to other factors including temperature. How sensitive was the first demonstration that we saw on the booth. One of the company’s staff put their hand onto the surface of an OLED and the heat from her hand impacted the visual quality. Ignis’ transistor configuration and driver architecture can read that temperature effect and can then compensate for it.

Ignis can measure the temperature effect on the OLEDs

Ignis can measure the temperature effect on the OLEDs

The degree of temperature sensitivity was a surprise to me – I had heard that OLEDs are sensitive, but hadn’t realised that they were that sensitive!

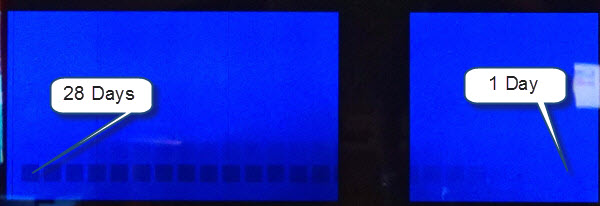

OLED materials, like all emissive displays, degrade over time and broadly in proportion to the total light produced. This is what causes “burn in” on OLEDs (and previously on CRTs and PDPs). Again, Ignis has tested burn in and found that within a day or two, visible defects can be shown, as you can see in the image below.

The burn in on the blue, of course, is very apparent Ignis showed us how it was able to compensate for this burn in, which is worse on blue than on other colours. OLEDs suffer from differential aging, which means that the colours fade at different rates. This is another factor that needs compensation.

The burn in on the blue, of course, is very apparent Ignis showed us how it was able to compensate for this burn in, which is worse on blue than on other colours. OLEDs suffer from differential aging, which means that the colours fade at different rates. This is another factor that needs compensation.

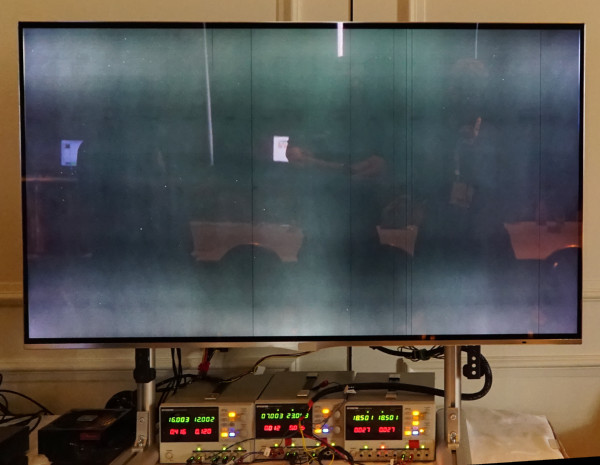

The company has also taken commercially available panels and deconstructed them to see how they look with “no compensation”. They then developed compensation and were showing the before and after effect.

This uncompensated OLED panel shows how much needs to be done to deliver a good image

This uncompensated OLED panel shows how much needs to be done to deliver a good image

This really brought us to the commercial point. If you can compensate for this kind of variation in panel manufacture, you can broaden the process window for making OLED panels, and could also significantly increase your yield. It might even be the difference between bringing a product to market or not.

To achieve the results it is getting, Ignis said that there has to be tight integration between the pixel designer, driving, measurement, TCon and compensation. Voltage shift is a big problem that needs to be corrected and the company told us that it sees variations of 2V (from 16V) in the V+ of typical backplanes.

Compensation can also be applied across multiple panels to match performance. While this may not be important in TV applications, it could be critical in automotive use of OLEDs. High-end car makers will not want different colours and brightnesses across different parts of a display group as it ages.

One of the hot topics for us at Display Daily and in our subscription newsletters over the past year has been high dynamic range, and Ignis said that its technology could be used to boost peak brightness to 1,000 cd/m², which, given the better blacks on OLED, could help to keep the technology in the TV battle as LCD makers boost up brightness.

We raised the issue of frame rates. When we spoke to LG Display at last year’s show, we heard that one of the challenges of moving to UltraHD is that the time you have between lines and frames is reduced, which means you have less time to compensate. Higher frame rates make this worse, but Ignis told us that one of the demos in the suite was running at 120Hz in UltraHD, the speed being achieved by the use of comparators, rather than the ADC converters used by others.

Ignis was also showing the 1,200 cd/m² (peak) mobile panel that it announced a couple of weeks ago (Ignis Claims HDR Mobile Display). It looked great (but we weren’t allowed to take pictures!), but especially compared to a Samsung Galaxy. Ignis used a torch to push the Samsung into its automatic high brightness mode, but that really killed the colours, and was still much less bright than the Ignis panel.

We heard that products using Ignis technology should be in the market in 2016 with “many more” by 2017.

Finally, the compensation technology also has applications in LED backlight compensation for LCDs and in emissive QD displays.

Bob Raikes