A couple of weeks ago, Barry Young of the OLED Association suggested that Chris Chinnock and I had ‘drunk the Kool Aid’ in accepting arguments from quantum dot suppliers at the recent SID event and questioning the viability of OLED TVs. Rather than have Barry set out my position, I thought I’d take the chance to set out my point of view.

Over many years, (I found a reference to already having said this for several years in an editorial from 2007!) I have said that every time I see an OLED TV, my heart knows that OLED will win. I may have said this as long ago as 2002, when Sony showed the first OLED TV panel that I saw at SID and when it said that it would be in the OLED TV market around 2005.

Barry is right, the OLED TV that LG showed at SID was fantastic in contrast and black level. It won my heart again.

However, I have also said that my head understands the importance of LCD. The reality has been that OLEDs have been incredibly difficult to make and to develop with high performance and long life. Back in 2003 or so, David Fyfe, then of OLED material maker, CDT, said at the DisplayForum conference that there were four big challenges in developing OLEDs. One of the challenges was the performance and lifetime of blue materials. At the event, Fyfe said that CDT was “Close to a breakthrough on OLED life” (and that was the title of our article). Now, it turns out that the lifetime of blue OLED materials remains a real issue.

In his article, Barry said ” Unlike LCDs, OLED material is in the very early stages of development”. If that’s really the case, then I’m tempted to add, like the joke about gallium arsenide, “and always will be”. The reality is that LCD materials and the quantum dots that Barry had in his sights are also still in development. LCD and quantum dot performance are a ‘moving target’.

Of course, at the recent SID, and on our website, we have talked about the promise of TADF materials that may represent a breakthrough in blue life. Given that the investors in Kyulux (one of the firms developing the material) include Samsung Display, LG Display, JDI and JOLED, it seems reasonable to assume that the firm has some interesting technology, but I’m going to have to drink their Kool-Aid if I’m going to buy into the idea that it will solve this long standing problem very quickly. Cynora of Germany also has some interesting claims for TADF. Of course, I’m optimistic, but it has been a long road.

Another of the problems that Fyfe set out in 2003 (and these were summarised again by UDC three or so years ago) was the patterning of OLED materials. That’s difficult enough in small sizes (although Samsung seems to have the problem solved) but incredibly difficult in large sizes. So difficult, that Samsung gave up the attempt to use evaporation for OLEDs for TVs. Now, the answer to this is to use a different deposition system, and inkjet printing has been a long promised solution (pardon the pun). Again in 2003, Fyfe said that inkjet is the way to go and CDT bought Litrex to develop that technology. At SID in 2016, Kateeva said that it would have ink jet printing of large OLEDs within a couple of years.

Kateeva has a track record in helping to solve the third of the issues that was discussed back in 2003, encapsulation, so it may well be right, that it can inkjet print large displays soon. We shall see.

The final hurdle to be overcome is in developing the transistor arrays needed to drive OLEDs. Again, this has been solved for smaller displays using LTPS, but not for larger displays. Having said that, work by LG and Sharp on large area oxide-based substrates has been progressing and that may be good enough.

Barry points out that LG may be getting yield of as little as 50% in its OLEDs, which are based on white OLED creation with colour filters, a ‘bodge’ by early OLED developers who couldn’t pattern the OLED materials, and which throws away most of the light (and one reason for the low peak brightness of the LG panels). Given that the firm has already had production for several years, and this is reckoned to be the ‘easier’ way to make OLEDs, that’s not very reassuring. As he says, LG needs to get to much better yields to reasonably compete with LCD.

Another of my long term sayings is that “OLED is the Trintron of flat panel TV”. In other words, Sony had a perfectly good business based on its unique Trinitron CRT. It looked better than other sets, and was unique to Sony, who could charge a premium. That wouldn’t be a bad end point for OLED TV.

As Barry again says, it may turn out that MicroLED or some other technology may yet come up to attack OLED, but like him, I have seen many technologies try to take on “the LCD Monster”. Maybe every new development needs someone to drink the Kool-Aid? Bob Raikes

(It has also occurred to me that rather than use white OLED and a colour filter, LG could try to exploit quantum dots by switching to a blue layer and putting the quantum dots where the red and green filters currently are. That would avoid throwing away much of the very valuable light, without meaning a need to pattern the OLED material).

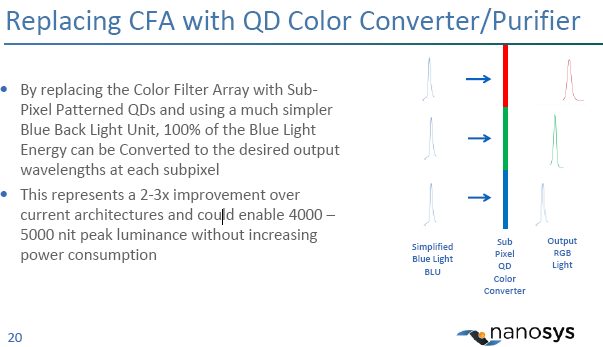

In this slide by Nanosys on QD architecture and presented at the SID Investor’s conference, the idea of putting the QDs where the filter traditionally is was raised. But why not use a blue OLED to generate the light?

In this slide by Nanosys on QD architecture and presented at the SID Investor’s conference, the idea of putting the QDs where the filter traditionally is was raised. But why not use a blue OLED to generate the light?