Are you good at fractions? You need to be when you are dealing with the image format of displays. The display world started with 4:3 aspect ratios, and then “SXGA” used 5: 4. The migration to widescreen 16: 9 has now been largely completed and mobile devices are extending the image format to 2: 1. However, there are applications that cannot do much with the display areas available in mainstream formats. For example, in a signpost, a very slim display would suffice. There are various approaches to producing such a display.

Unusual display formats

In order to meet the demand for LCDs with special aspect ratios, there are basically two approaches. Either:

- a display is developed and manufactured precisely, or

- a large-format display is cut to size.

Both methods have advantages and disadvantages: The development of a customer-specific TFT requires a lot of development cost up to several €100,000s, and the number of pieces must be high enough that it is worth stopping the production line to convert to the special format.

It is sometimes easier to cut a suitable display from a commercial panel. In addition to the display panel itself, the LED backlight, the frame (bezel) and the entire film stack must be adapted. Taking a longitudinal section usually creates displays with aspect ratios of e.g. 32: 9 or 16: 3. What are the requirements for a display to be suitable for cutting?

How can you cut TFT LCDs?

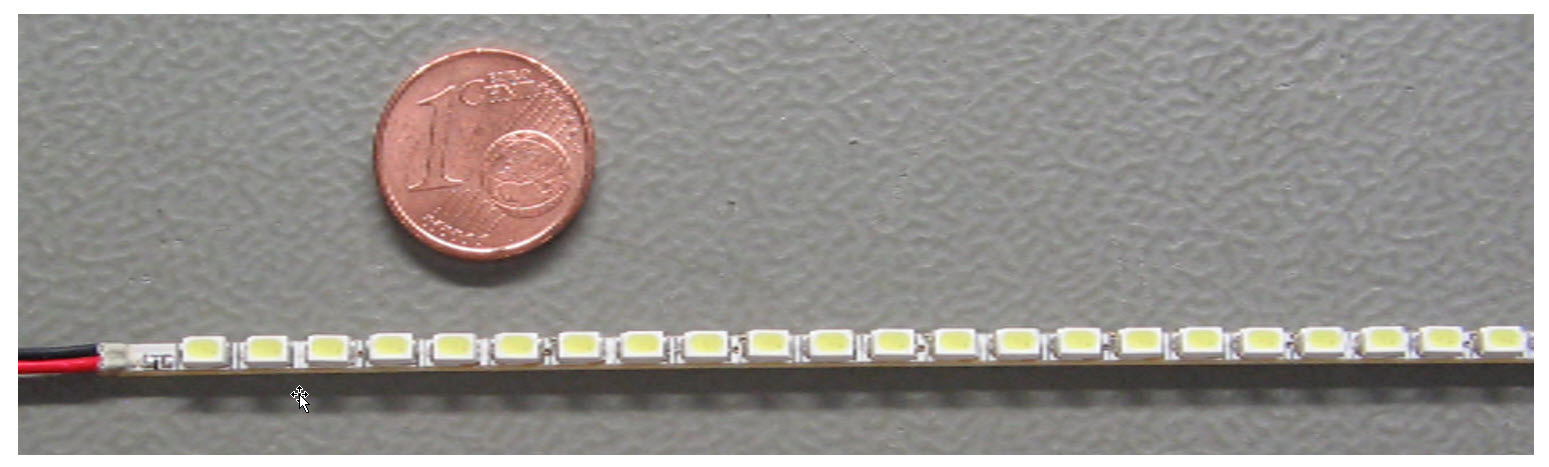

An LCD display modulates the white LED shining through from the backlight where the LEDs are arranged on a strip-shaped circuit board as shown in Figure 1.

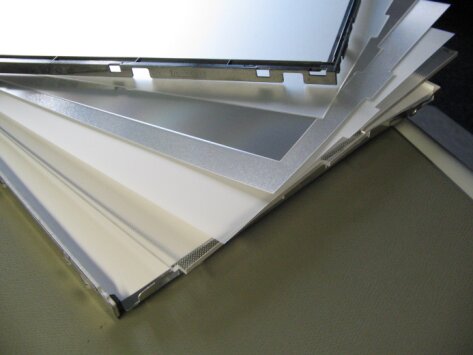

The light is scattered across the surface by a diffuser plate. Before it reaches the display glass, it passes through various optical foils that condition it for use. Figure 2 shows the structure of a typical TFT module, below is the back of the module, followed by the diffuser, foils and finally the panel (not shown). The mounting frame, called Bezel, holds all components together.

Figure 2: Film stack of an LCD module

Figure 2: Film stack of an LCD module

LCD panels consist of two glass sheets, between which the liquid crystal material is held. The alignment of the liquid crystal and thus the light permeability are determined by an electrical field, which emanates from electrodes on the inside surfaces of the two sheets. These are controlled by driver modules, which are placed separately on the edge of the glass in the x (columns) and y (rows) directions. In the case of displays with a higher resolution, several ICs are connected in series. There are two or three ICs for the 1,080 lines of a FullHD display.

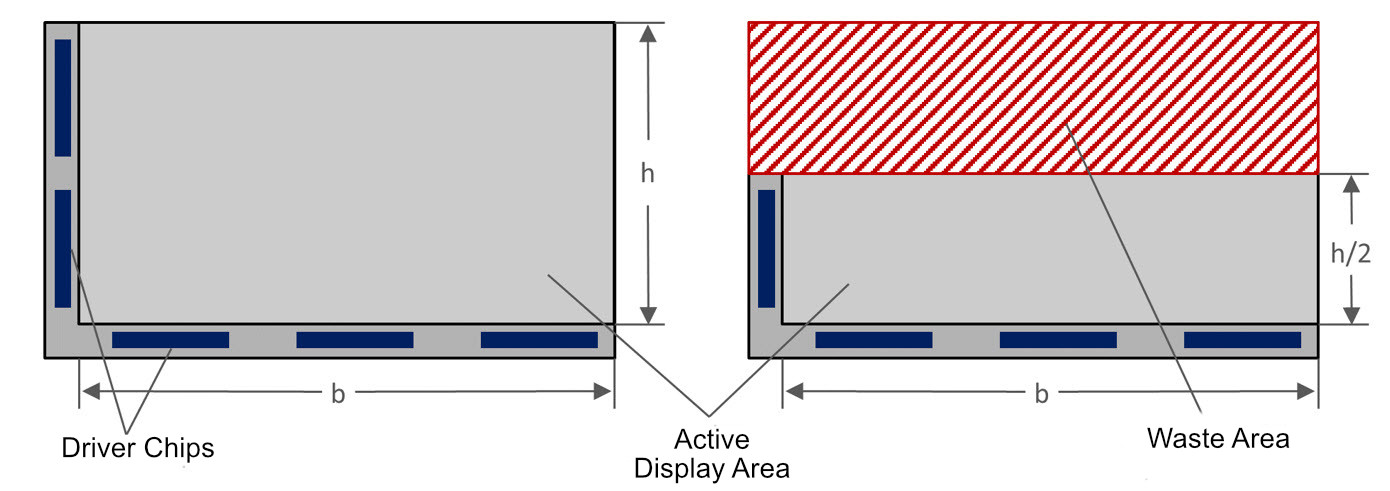

If you disconnect the lines behind the first or the second IC, the partial display can continue to function. The arrangement of the ICs suggests possible division points: the display can only be cut in such a way that the outputs of an IC remain completely intact, i.e. only in integer fractions. Manufacturers refer to the elongated display as a “stretch display” or “bar type display”. See Figure 3 for a display that has a 32: 9 format after cutting. As long as there is a row and column driver for each pixel, the shape of the display is immaterial. The optical properties and environmental operating conditions of the original display are retained despite the cutting.

Figure 3: Horizontal section on a “half size” display

Figure 3: Horizontal section on a “half size” display

Electrical control

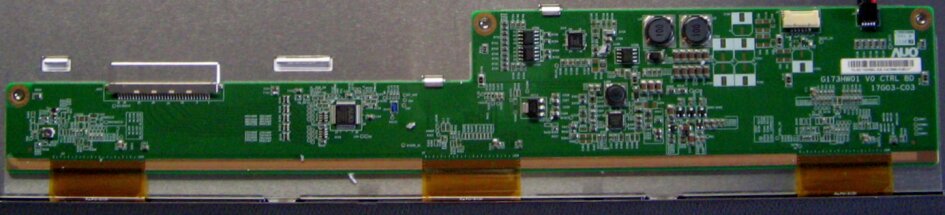

Figure 4: PCB of the timing controller

Figure 4: PCB of the timing controller

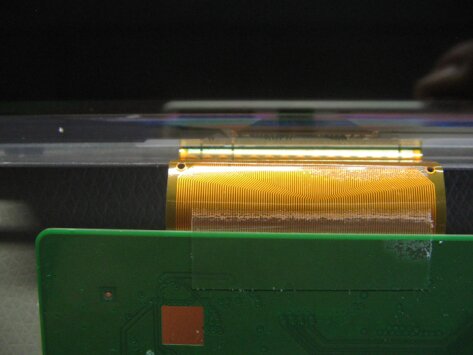

Figure 4 shows the circuit board of a timing controller, which converts the LVDS signal coming from the LCD controller into control signals for the drivers, which are connected via flexible foils. While the connection (see Figure 5) between the circuit board and the glass has only a few dozen lines, the driver ICs, which are located directly on the glass, have several hundred outputs to control the display segments. Other components on the board generate the voltages required to operate the display and the LED backlight.

Figure 5: Connection between timing controller and LCD panel

Figure 5: Connection between timing controller and LCD panel

With special shaped displays, the timing controller board remains unchanged and does not “know” about the reduced number of driver outputs. Since it is controlled with the timing of the original module (e.g. 1,920 x 1,080), the timing parameters of the control are unchanged. Only the application software has to take into account the changed format of the actual physical screen.

Original displays in unusual formats

There are also displays needed for some applications with square or round formats. Small displays of this type may use a single-chip TFT controller that is integrated as chip-on-glass on the panel. The chip combines the functions of the timing controller, drivers for rows and columns and also the frame buffer. The host interface does not work in a PC environment, but with an ARM or other microcontroller. In addition to a MIPI bus, the display can be updated via SPI or a CPU bus. To relieve the burden on the system controller, the color depth can be reduced from 24 to 16 bits in many applications.

Single-chip displays are common in diagonals up to 5″ and with a resolution up to 720×720. There is a 26.5″ display from LG Display, on the other hand, that offers a high resolution in square format with a 1920 x 1920 pixel format and is connected via LVDS. Displays with an aspect ratio of 3: 2 are used in tablet computers such as Apple iPad.

Displays with a circular image section

Smartwatches or fitness trainers often use round displays. The control lines for rows and columns are routed at the edge of the viewing area. In the display shown in Figure 6, the driver is a single-chip solution at the lower end of the glass, so that the housing must be shaped accordingly.

Figure 6: Small format display with a circular image area

Figure 6: Small format display with a circular image area

Examples of use

Cut displays can be used where information mainly has to be output in text format, e.g. use for a transit stop announcement, a seat reservation, a route map or a variable signpost in a conference building.

The square 26.5″ display from LG Display (which is made as a native panel in that format, not cut – editor) is well suited for displaying measured values ??from systems such as radar or sonar that offer a circular cover. Small square displays fit in switch boxes in home automation.

Figure 7: Square display in a radar device Figure 8: Square display in a sonar

Figure 7: Square display in a radar device Figure 8: Square display in a sonar

Click for higher resolution

Round displays are also used in industry as intelligent round instruments that not only record and display measured values, but also transmit them to the control center. They can be used to display not only a measured value locally, but also a trend or a warning function that can provide the employee on site with valuable additional information.

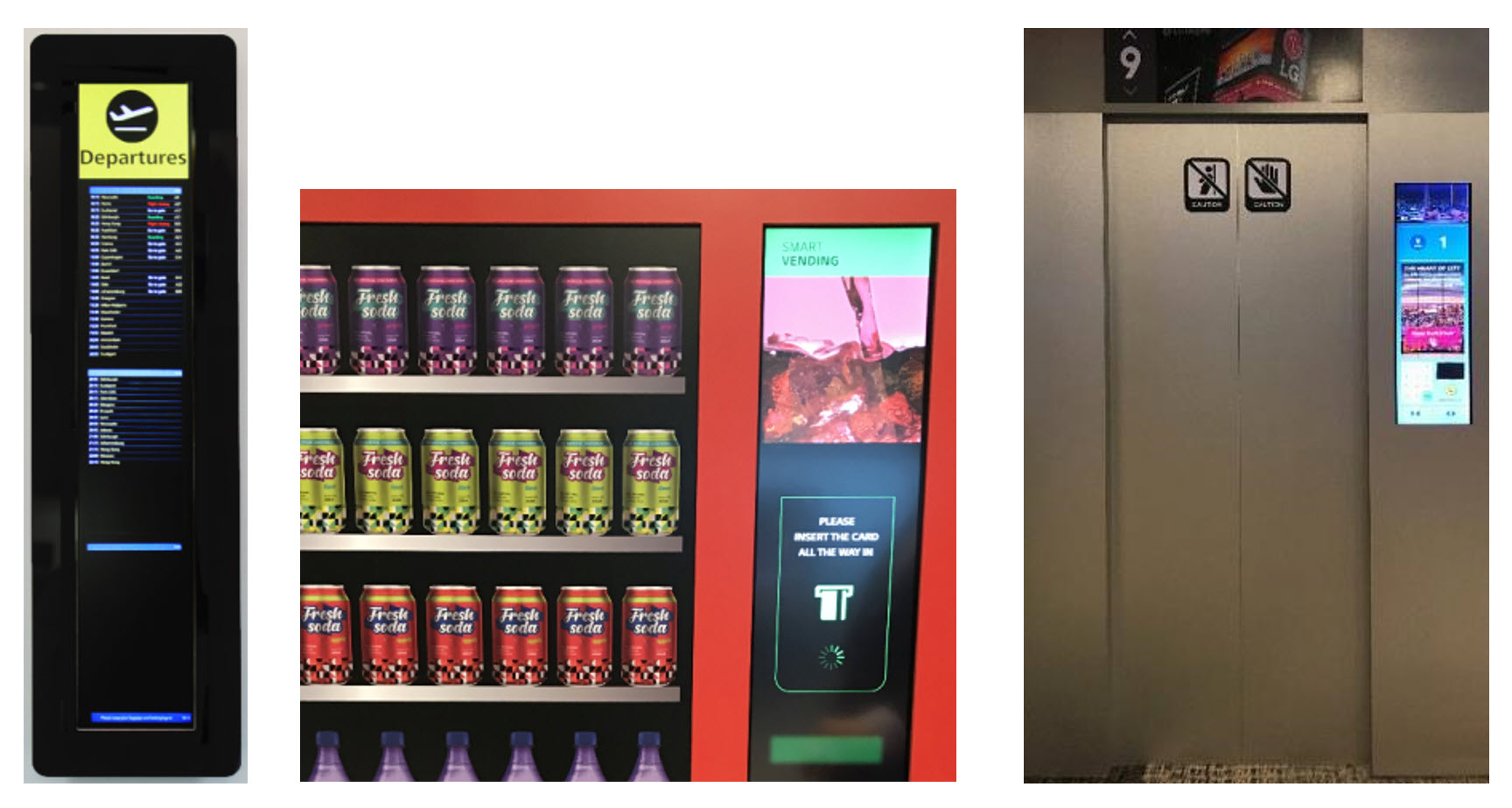

In portrait format, slim displays are used where long lists are usefuk (see Figure 9) or where space is to be used at, for example, a drinks machine or elevator control. Provided with a touchscreen, they offer the customer added value by giving the beverage vending machine further information on the selected product or by displaying alternatives.

Figure 9: Departure times Figure 10: Vending machine Figure 11: Elevator

Figure 9: Departure times Figure 10: Vending machine Figure 11: Elevator

Click for higher resolution

A special solution can be implemented with the Electronic Shelf Label Display from LG Display (see Figure 12). The touchscreen uses “In Cell” technology that is designed as an integral part of the display and is located inside the LCD cell. The driver IC operates both the display and the touchscreen, without mutual interference. At only 48mm high, the display is slim enough to replace conventional labeling on the shelf.

Figure 12: Electronic shelf label display in a supermarket

Figure 12: Electronic shelf label display in a supermarket

This narrow ‘strip’ display can also offer added value in household appliances such as washing machines, dishwashers and stoves.

Conclusion

Displays with special formats are used in confined spaces, or where the content needs a certain format. Larger displays can be made by cutting, while smaller ones tend to be already made with special dimensions and shapes. In combination with a touchscreen, a display can enable new user interfaces and interactivity can make the end product more versatile for the user and more attractive for the end user. The designer can have a large variety of displays with special formats to choose from. (RS)

This article was written by Rudolf Sosnowsky who is Technical Director / Chief Technology Officer of Hy-Line Computer Components Vertriebs GmbH and was originally published in German as a white paper. It was translated by Meko Ltd and is republished with kind permission.

HY-LINE Computer Components Vertriebs GmbH https://www.hy-line.de/

Tannas Electronic Displays, Inc. https://www.tannas.com/