I have been interested in the idea of dual LCDs for quite a few years. At CES in 2007, Sharp showed its ‘Mega Contrast’ panel which had contrast of 1,000,000:1, but about which the firm would say little. I pondered for a couple of days about how it might be done, then suggested ‘do you use dual LCDs?’. They smiled, but wouldn’t confirm.

Nothing seemed to happen to the concept of the dual modulator (one to control the backlight and one to control the colour) until Panasonic introduced its high end dual LCD panel for broadcast monitoring. At IBC in 2017, I got the chance to see Eizo’s monitor which used the panel next to a high end Sony broadcast OLED monitor. (Eizo Planning CG3145 High Contrast Monitor Shipment)

It was an ephiphany for me. Until then, for many years I had said that, side by side, I would always choose the OLED. “OLED had my heart, but LCD had my brain”, I have said many times. However, at that demo, for the first time I would have chosen the LCD. At low levels of luminance, the monitors looked very similar, but as the brightness went up, the OLED looked worse and worse, while the LCD looked better and better. This is because the LCD was capable of ‘full colour volume’ – that is maintaining saturation as the luminance got towards the limit of the display, while the OLED colour shifted and lost saturation above a certain point. The OLED also had a little alarm which warned when you got to the level of luminance where this limiting started.

Dual Panel Comes to TV

Anyway, I was then pleased to see over the last couple of years a lot of development work going on to develop the technology for TV. At CES in 2019, Hisense, among others, showed a dual panel TV using a 4K panel on a FullHD modulated backlight.

Hisense Dual LCD TV at CES 2019. Image:Meko

Since then, there has been lots of talk about dual LCD for TV, and BOE is still developing the idea, it reports. (The company made surprising claims about power efficiency – a long term concern about the idea – at the SID Business Conference, and I plan to return to this topic). There are actually sets on the market (although only a few and in a few markets) now. You can find articles tagged with the topic on the website here.

So, to get to the news in this article… During the DSCC/SID Business Conference, Chuck Milligan of Flexenable mentioned briefly that his firm’s flexible LCD technology could make very thin dual panel LCDs, thinner than single glass LCDs.

“Ah”, I thought, “that could be really useful for automotive makers”.

Auto makers are looking for really deep contrast, so that the rectangular shape of most displays can be hidden, but they are also looking for conformable displays that can be shaped to match the organic shapes that their designers like. On top of that, auto makers are comfortable with qualifying LCD for their application – something that has been challenging for OLEDs. As the saying goes

“What’s not to like?”

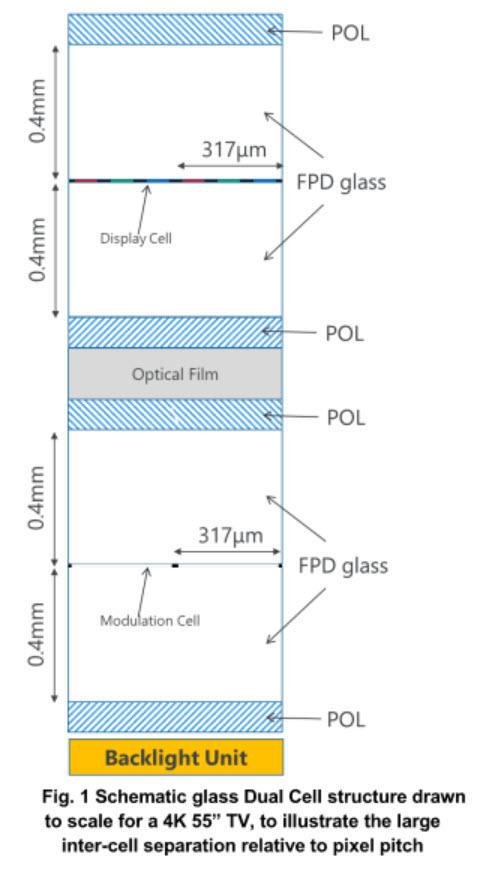

I followed up with Paul Cain who is Strategy Director at Flexenable. He gave me more details on the advantages of the use of the firm’s organic transistors, which can be deposited at low temperatures on film. There are a number of problems with the use of glass in dual LCDs, he explained. Effectively, the depth of the display is several times the typical pitch. That means that the light spreads, so the dimming level is not really at pixel level. Further, you typically get moiré issues because of the close match between the modulator and the imager panels.

A typical dual cell stack – from the Flexenable paper at IDW

A typical dual cell stack – from the Flexenable paper at IDW

To eliminate this moiré effect, you typically need a diffuser between the panels when using glass. As well as causing more light spread, this kills the polarisation of the light from the modulator. That means you need two complete panels each with dual polarisers, rather than just three (with the modulator and imager both exploiting a middle one). The final panel can be 1.5mm to 2mm thick, which causes all sorts of diffusion and viewing angle issues. Further, curving a dual glass LCD is extraordinarily difficult. (I’d say impossible, but ‘don’t bet against the engineers’).

Flexenable can use TAC film which is typically just 40 microns thick, so about 10 times thinner than glass. Because of that, you can make a complete dual LCD stack with a thickness around 300 microns (on the first sample with a paper presented at IDW last year). Because the stack is so thin, you can eliminate the diffuser, so you can also maintain polarisation and save a polariser. Even better, in the longer term you could use the polariser layer to deposit the transistors saving even more materials and thickness. Flexenable presented a paper at Display Week (session 85.1 – Organic LCDs Using Polarisers as Substrates – Enabling Pixel Level Dimming in Dual Cell LCDs).

Cain reminded us that its technology can support 300-350 ppi pixels and has mobility that is between amorphous silicon and oxide, so could be used for other applications. Notebooks and tablets are also potential target markets with OLED-like blacks, but without the lifetime issues.

Finally, we turned to commercial issues and Cain confirmed that Novares, an automotive supplier, is still very involved with the firm (Novares Invests in FlexEnable). The firm is no longer working with Truly in China, but has its own office in Taiwan (which has made a big difference during Covid) and there is collaboration with other fab owners in the region.

Just for completeness, there are a number of non-display liquid crystal applications that are of interest in automotive and the company continues to collaborate with Merck. (For Flexible Displays, We don’t need your stinkin’ OLEDs!) (BR)