I almost dropped my spoon. I was watching the IMID Keynote from Samsung Display Corp (SDC) CEO JS Choi. He announced a new vision for the future of the industry’s number 2 (by revenue) display firm, with the aim to become a $50bn company. OLED 2.0.

This included many thrusts but the important ones are:

- to develop the Smartphone business by emphasising the refresh rate, increase the colour depth and add OPD full screen security,

- to use Gen 8.7 processing techniques to enter the OLED notebook and tablet market in a big way,

- to move strongly into the Automotive OLED market and

- to enter the micro display market (probably OLEDonSi) for AR-VR displays.

I almost dropped my spoon partially because he had just validated the need for full screen security on a smartphone display. This is something that my client, ISORG in France, has been working on for over a decade. Until this point, smartphone security had been based on one of the following four technologies:

- Optical,

- Capacitive,

- Face ID or

- Ultrasound.

All of these technologies, bar the Face ID, have been focused on single finger authentication: you put your finger on the display, in some cases with OLED, on an indicated point and the sensor behind the display validates your input.

But now JS Choi had validated, as only a leader in the OLED industry can, the role of OPD (Organic Photo Diode) as a full screen sensing and finger print technology. He explained how multi-finger authentication (for example you put your four fingers on the display) leads to security 2500 million times higher than a single finger. Choi said that Samsung aims to deploy in-cell OPD within the framework of their new growth strategy

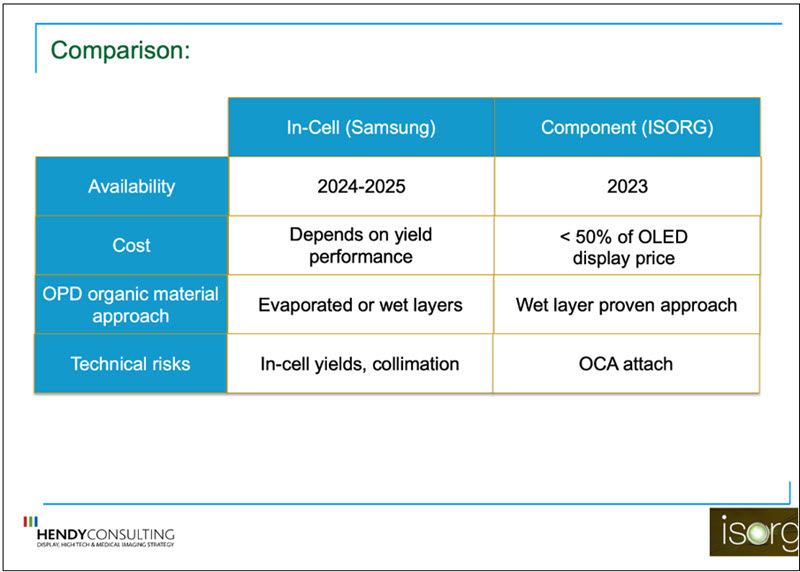

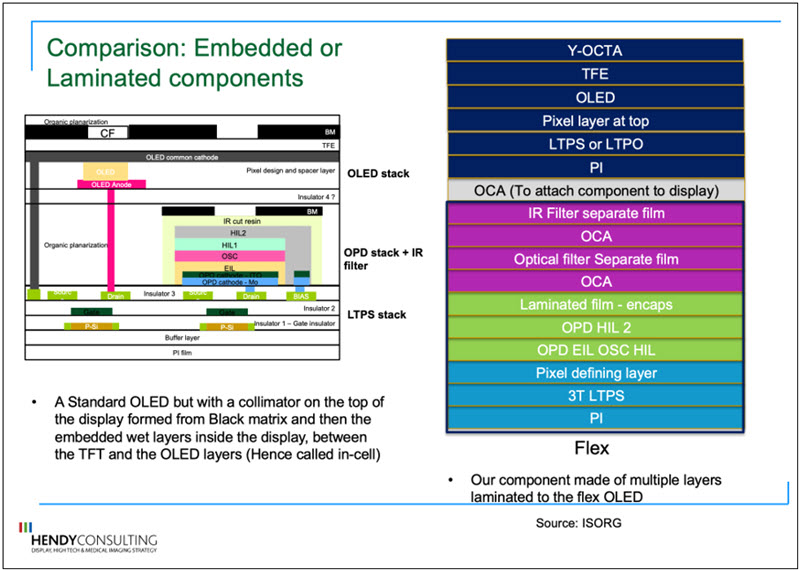

Now there are two different technical architectures to OPD: in-cell, as is used in the Samsung SDC case, and a component-based approach, as is the case of ISORG, as shown in Figure 1, below. It is important to note that there are two main parts of a OPD sensor from the display point of view. First, there is a mechanism to collimate light within the display and second the layers of the OPD sensor itself.

Figure 1: Two different approaches to OPD sensing technology. Note high refractive index materials as per the MLP approach may also be used to support the collimation in the in-cell approach

Figure 1: Two different approaches to OPD sensing technology. Note high refractive index materials as per the MLP approach may also be used to support the collimation in the in-cell approach

The SDC approach is an in-cell approach and may well use a black matrix type collimator at the top of the display (or rely on the POLless technology that is already there) and then build the rest of the sensor into the stack itself between the TFT and OLED layers. This is an additional 5-mask process, and does indeed add some additional TFT complexity to the total layout. As was seen in earlier iPhone 5 days when touch moved in-cell, this method does potentially bring some yield risk as a high complexity additional function is built into the display itself. In the iPhone 5 days, there was public discussion of a 50% yield hit.

Alternative 2

The alternative is ISORG’s component approach. This achieves the same end result and is already demonstrated: it could be ready for mass production next year. A full sized separate sensor is manufactured and then laminated, with a very known process using OCA (optically clear adhesive) to the OLED display. This is a very high yielding approach and available for the market very soon, whereas it looks like SDC will need some time to pull off their in-cell approach. The best summary is indeed this, that it is the trade off of yield risk of having a novel set of active layers in the middle of the device, vs laminating a separate component in a very well understood process.

One of the major benefits of OPD technology is the maximum of pixel sensitivity in the visible range (RGB of the display) compared to other optical technologies allowing high image contrast even for display of lower display transparency cases such as 4K (OLED) or even POLless displays. This is enabled by the electro-optical performance of the organic semiconductor that has a light absorption reaching near 100% and quantum efficiency above 80%.

For the light collimation, this function is essential to ensure good contrast between ridges and valleys as the finger is placed at a certain distance from the image sensor (mm scale) and so will directly impact the fingerprint authentication effectiveness for the most challenging fingerprint types (which tend to be Asian women with their very small fingers, with very high pattern resolution) and also for difficult usage conditions (dry skin, cold environment).

The Benefits?

And what are the benefits of such an approach? Well for the consumer, much higher security for our data and financial transactions for our smartphones. One could alternatively imagine that you could select and authenticate a single app on your phone by putting a finger down in that place on the screen to open it. That’s better than old fashioned password entry or multiple gestures. For leading high end smartphone device makers, it is the option to move now into offering a new level of security to clients at a modest price.

For SDC it is the potential of a way to maintain their price line for 6” OLED displays which has now fallen from the heady heights of $110 per display when flex OLEDs were launched to around the $40 per display area now. And for ISORG in France that has been working on OPD technology in France for almost a decade, this is validation of the technology. The technology is available for integration now. (IH)

—

This article has been moved outside the Display Daily paywall by ISORG, so will not count as one of your two per month free mailshots if you are not a paying subscriber. Thanks to them.