There is no doubt that the technology topic that has generated most interest over the last few months is microLED, although after SID I think miniLED may also have quite an impact, too.

We think of microLED as those of less than 100 microns, per side, and down to as small as three to five microns per side. MiniLEDs are those of around 100 µm and up, although I’m not quite sure where the upper limit of miniLED really is – perhaps 0.5mm? The main impact of miniLED, it seems is going to be in supporting direct backlit LCDs and delivering the deep blacks that are reminiscent of OLED displays. Companies have shown LCDs with these backlights from a few inches in diagonal, and intended for VR applications, up to TV sizes.

These miniLED-backlit displays look very good and can support HDR and high brightness with very little ‘halo’ effect if they are well designed. The first to want this kind of deep black were the automotive buyers, who are attracted by the look of OLED, but who are reluctant to commit to that technology as they are either not confident in the technology or cannot yet qualify it for automotive use.

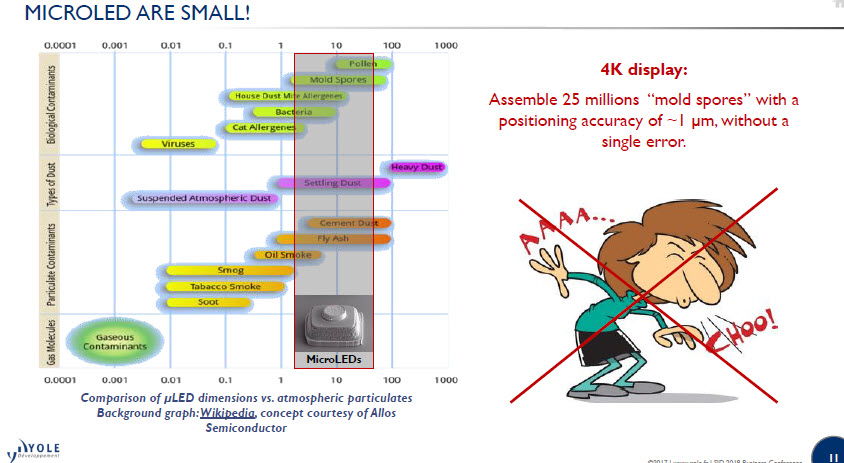

MicroLED on the other hand is aimed at microdisplay applications such as AR headsets, where the high brightness and high efficiency are very attractive, or for use in ‘distributed’ ways in other applications from wearables to digital signage, and including TV. In these applications, the microLEDs have to be ‘spread out’. Now, there are a lot of challenges in this – checking and spreading out 24 million LEDs (for an UltraHD TV) or 96 million LEDs (for an 8K TV) is going to be quite a challenge, especially if you want to compete with LCD and OLED on price.

At the SID Business Conference, Eric Virey of Yole Développement, who has provided some Display Daily articles for us, explained the progress in the market and showed an excellent slide that emphasised the small size of microLEDs, when compared to some other particles in the environment. (see BC04 MicroLED Continues to Throw up New Challenges for a full report on his talk – subscription required),

Now, one of the challenges for LEDs is in getting consistent performance, both in brightness/efficacy and also, importantly, in chromaticity. One of the key technologies in making the large LED displays we see in cities around the world, is having ways of sorting and selecting the LEDs to look good. Good installers will buy extra modules when they have a new display so that they have modules that match in performance if maintenance and repair is needed. That variability is likely to extend to microLED displays and LEDs can also be defective. Therefore, it will be essential to have some kind of quality checking between device and display.

At the conference, Virey said that one way to solve a lot of the problems is to use the concept of redundancy, that is, supplying two LEDs for each pixel. If you do that, you should get very few visible defects. It just means double the number of LEDs!

I titled this article ‘MicroLED May Drive You Mad’. However, it may be more accurate to say that trying to drive LEDs may make you crazy! Ask any big LED maker and they will tell you how hard it is to drive LEDs to get good grey scale. Because they are diodes, driving is best done with pulse width modulation and high quality big LED displays are driven at over 3kHz to deliver good performance at low levels of brightness, where the duty cycle of the PWM has to be very short.

Unfortunately, you can’t use current control to drive the LED, as, and this is as I understand it, because the current level changes the temperature of the LED and that changes the colour of the light emitted. That makes driving the LEDs very tricky, especially if you want a very simple driving circuit using the kind of low quality silicon that is currently (sorry for the pun!) used to drive today’s LCDs and OLEDs.

Some approaches to this challenge suggest that you may not use the kind of architecture used for todays flat panel displays, but instead you might use an approach that puts a driver chip, using high quality crystal silicon, on the substrate, rather than a-Si or even LTPS TFTs. One driver chip could support quite a few pixels. Perhaps one driver for every 64 LEDs? (That is the approach of X-Celeprint X-Celeprint Shows 5.1-inch MicroLED Display) That would mean nearly half a million on an UltraHD TV. Of course, if you are making microdisplays, you might be able to use a CMOS backplane that could include the drivers as part of the architecture.

I would welcome any feedback on this topic – I think it’s going to be important! (BR)