Every year in March, the world’s experts in QDs convene for the Quantum Dots Forum to discuss recent advances, market conditions, and new implementations of QDs for displays and other applications. This year’s QD Forum featured talks from consultants, corporate scientists/CEOs, academics, display giants, and start-ups, all with their own unique role in QD materials development and commercialization.

Every year a theme arises, and for the past few years it has been that QDs are finally mainstream. This year, however, the attitude clearly shifted from “we made it!” to “what’s next?” Now that QDs have penetrated the display market, the community is focused on extracting the greatest benefit from these tiny but powerful light-emitting particles.

Every year a theme arises, and for the past few years it has been that QDs are finally mainstream. This year, however, the attitude clearly shifted from “we made it!” to “what’s next?” Now that QDs have penetrated the display market, the community is focused on extracting the greatest benefit from these tiny but powerful light-emitting particles.

In this blog I’ll highlight some key takeaways from the conference about the future of QD technology in displays.

Quantum Dot Color Filter Replacement

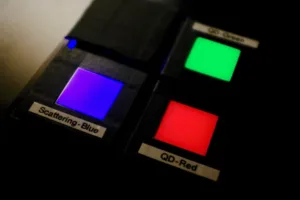

QD color filter replacement (QDCFR) was a hot topic this year that was barely mentioned at last year’s conference. The advantages are great (efficiency, brightness, viewing angle, color) but the challenges will not be easily overcome. One of the major challenges that QDCFRs must overcome is the development of an in-cell polarizer. QDs depolarize light, so they must be used after both polarizers in an LCD. There were mixed opinions on how difficult this might be to accomplish, but one alternative stood out as a possible workaround – use an OLED backlight instead! An OLED/QDCFR technology could take advantage of the black levels provided by OLED while exploiting the efficiency and color of QDs. It remains to be seen if OLED/QDCFR is a viable product, as the cost is expected to be higher than both QLED and OLED displays.

Red, green, and blue QDCFR on display at CES 2018 (courtesy of Nanosys)

Non-Cd ELQD (true QLED)

Of course, the ultimate goal of QD display technology is an electroluminescent (EL) QD device (some call this a true QLED display). The promise of an electroemissive technology based on QDs has been the pipe-dream of QD and display scientists since it was first demonstrated over a decade ago. Nearly all developmental work has occurred on Cd-containing materials – but that’s changing. There is an increased focus on InP-based ELQD devices.

Nanophotonica, Fraunhofer, and Seoul National University all shared data on their progress related to InP ELQD. Not surprisingly, the lifetimes are very poor (you can watch it degrade within one working day), but so were CdSe ELQD devices when they were first being developed. But the efficiencies of the InP devices were quite impressive, given they are still in their infancy. There is hope still for highly efficient ELQD displays (Cd will come first), but of all QD display technologies, this one is still the furthest away from finding its way to our living rooms.

Ink-Jet Printed QDs

Cost is clearly a concern for anyone creating QD components. Ink-Jet Priinting (IJP) is one way to reduce cost and pattern QDs in the micro-scale. Based on talks from Kateeva, TCL, and Najing Tech, the ability to print QDs is well on its way to becoming a viable technology. Kateeva demonstrated that QDCF wells could be filled with QDs using their INP platform, while Najing Tech and TCL spoke about their full-color IJP ELQD displays.

An ink-jet printed 5-inch AM-QLED display (80 dpi) from TCL

Perovskite QDs

The battle between CdSe and InP QDs is now seeing competition from a third QD type – perovskites. This new material set contains some very attractive properties for displays (narrow emission & high blue absorbance) but have not yet seen commercial success due to two main factors – they are unstable in their operating environment, and they contain lead. Stability improvements are expected to continue in the coming years, and some people are working on Pb-free perovskites, but that is a long way off. For now, if display companies want to use perovskites they will be stuck with the difficult choice of whether or not they can tolerate lead in their display. The level of lead in a perovskite QD film is predicted to be less than the EU’s RoHS limit (1000 ppm) which means it would not require an exemption, unlike the current CdSe QD technology which needs one. Companies Avantama and Quantum Solutions were on hand to discuss their progress in this area and make the case for Perovskite QDs.

MicroLEDs

No display topic has been hotter this year than microLEDs (even if the Samsung Wall isn’t really a micro LED display). This year we heard from two companies in the microLED space, X-Celeprint and Lumiode. While neither company focuses on QD development for microLEDs, the audience was clearly interested in how QDs could play a role in what some believe is the future of displays. To achieve full-color, there are two general approaches:

- make R, G, and B microLEDs for each pixel (which may mean different semiconductor processes and different performance parameters for each colour – Man. Ed.)

- make only blue microLEDs and use down-converters to make the R + G subpixels. (using just one semiconductor process – Man. Ed.)

MicroLEDs cannot use phosphors to down-convert blue light to red + green due to the relative size of phosphor particles, which are larger than an individual microLED. Here is where QDs have a distinct advantage. Their small size and efficient down conversion makes them attractive for the microLED space, but questions still remain. Will QDs be able to absorb enough light to achieve full color conversion? How will QDs be deposited (IJP or photolithography)? Will QDs survive the conditions of on-microLED without further encapsulation? Suffice to say, there is interest on both sides but only time will tell if this will work out for mass production.

Conclusion

I look forward to joining this event again next March to learn and discuss how far QDs have come in 2018, and to find out “what’s next?” in 2019. – Peter Palomaki

Peter Palomaki is the owner and chief scientist at Palomaki Consulting, a firm specializing in helping companies solve big problems at the nanoscale. His utilizes his expertise in quantum dots and materials chemistry to solve challenging problems with clients large and small.

[email protected] www.linkedin.com/in/ppalomaki @nanopalomaki