The first session in the afternoon was on emerging technologies and applications to increase profit. There were 9 panelists and speakers overall.

Roman Maisch is a Senior VP at Merck and he looked at developments in liquid crystal materials in the main, first in displays and then in other applications.

There are trends in LCDs towards high transmission, high resolution, curved, non-traditional shapes, ultra fast switching, high colour gamut and glasses-free 3D. These all have different requirements.

Maisch started by talking about Merck’s polymer stabilised LC material which he said is now the most widely used LC technology in TV. It has advantages in improved transmission which helps with TV cost as savings can be made in the backlight components.

In IPS and FFS technology LCDs, transmission is improved by Merck’s UB-FFS technology. That also helps to enable the very high resolution displays.

Curved TVs are an interesting development. To enable curved displays in LCD, you need to maintain the cell gap despite the bending of the two glass layers each side. Merck has developed a “polymer wall” technology. In this technique, the LC material is mixed with a monomer and then under UV light, the polymer can be stabilised to build up a “polymer wall”. It also enables plastic substrates and allows for the use of very thin glass.

Frame sequential LCD has long been on the wishlist of LCD makers, as it eliminates the colour filter, but if you want to go to colour sequential technology, you need fast response. Merck is working on blue phase LCD and has got switching times down to around 1ms, but at the moment, driving voltages for this speed are too high at around 40V.

Uniform lying helix is another liquid crystal mode that is being developed, but still needs improved uniformity of alignment in the cell although switching can get down to below 1ms and 2.5ms grey to grey.

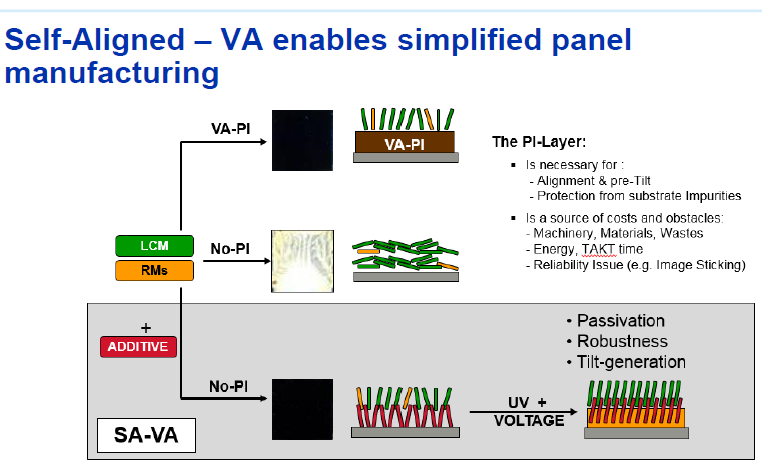

Self-aligned VA is being developed to eliminate the need for a polyimide layer for alignment. The polymide layer currently used provides alignment and pre-tilt for the LC materials, and also protects from substrate impurities. However, it can be a source of problems in manufacture which can reduce yield and takes TACT time. It also is one of the causes of image sticking. Merck puts an additive with the VA material and with an electric field, the additive is drawn to the substrate and then hardened by UV exposure. It is said to make the material more homogenous as well as improving yields.

SV VA from Merck eliminates the polyimide alignment layer

SV VA from Merck eliminates the polyimide alignment layer

Quantum Dots are under development by Merck including emissive QDs and Quantum Rods. QDs could be used in backlight films or emissive displays, while the rods could be used for colour filter production and even for novel displays based on switchable Q-Rod pixels.

Merck is working with SeeReal in Germany to develop 3D autostereoscopic displays. At the moment, gaming and medicine are target applications, although eventually markets could include TV. At the moment, it needs a lot of computing power to generate the images, but the project is developing.

Siloxanes were accessed by Merck following an acquisition last year and they can be used for a variety of applications including pixel planarisation, as a low-k dielectric for TFTs, for Oxide TFT passivation, to provide ‘optic-like’ lenses and light guides and for A/R coatings.

Turning to non-display applications, smart energy glass is being developed by the company for window applications. This is very interesting to architects as the switching is quite fast. Smart LC-based antennas can be used to make satellite reception antennas which can adapt to different conditions and be dynamically tuned. Finally, there are LC-enabled headlamps for cars which allow liquid crystals to steer the light from the headlight and make the headlights dynamic.

As well as LC materials, Merck has soluble and insoluble OLED materials.