John Brodd is CEO of Cima Nanotech which is making materials for ITO replacement. There are around 70 staff in the company, mostly in China.

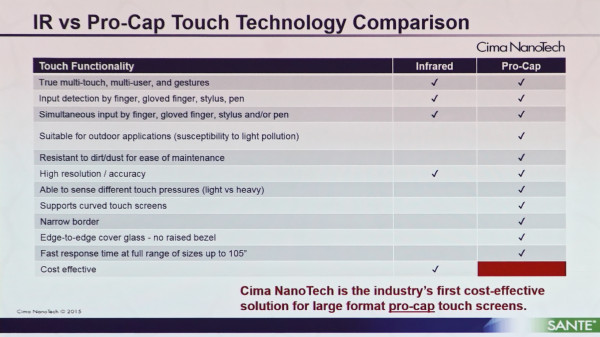

Procap touch technology is great, but runs out of performance at around 32″ diagonal when ITO is used to make the patterns. Cima developed Santé material which is around 15 times better in conductivity than ITO and that enables high speed procap even in large sizes. The company said that it “did well” at the recent DSE show. The firm has recently made a 100″ demonstrator to prove that its technology works well even at very large sizes.

Brodd said that a competitor doesn’t have to be as cheap as infrared, but you have to be close. The Santé material self-assembles randomly to avoid the moiré that is a challenge for metal mesh solutions.

Digital signage is really important in China. Education is also important in China where the government is looking at the classroom of the future, which would include large touch displays.

Cima is setting up a J/V with “the largest” OEM/ODM and expect an announcement in the summer, and Cima will look after sales of modules.

The company is currently in a capital round for $15 m.