SiliconCore was showing its 1.9mm Orchid displays which have been shipping for some time, but the big news was the public showing of the company’s new “Lisa” (LED in Silicon Array) architecture which the firm has been working on for a while. The technique changes the assembly of an LED display by moving from the current method where LED chips are packaged and then the packages are soldered (with four solder joints per LED) onto a surface to create the being. In the Lisa architecture, the chips themselves are bonded directly to the substrate, and known as Chip on Board (COB). We recently ran a Display Daily article about the Chip Scale Packaging (CSP) that allows the development of COB (CSP LEDs Are the Next Step in Development)

At the moment, the COB technology is being used in 1.9mm pitch displays and these will ship from June. However, the new architecture will help move to smaller pitches. The company told us that once ‘traditional’ architectures get down below 1mm pitch, soldering becomes very tricky and although production faults can be fixed, there is a cost and pixels can fail because of the solder. SiliconCore has a roadmap to start with 1.9mm, then move down to 0.95mm and then 0.475mm. By our calculation, that is equivalent to an 84″ UHD (or 42″ FHD) display and means that, in terms of resolution, LED will be completely competitive with LCD. SiliconCore believes that 0.2mm is the eventual limit, but that would mean the equivalent of a 35″ UltraHD display!

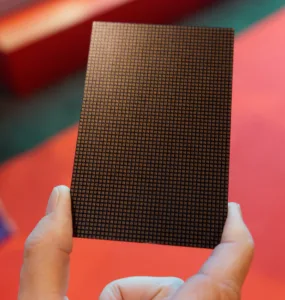

SiliconCore’s Lisa LEDs. Image:Meko

The other advantage of the technique is that the surface of the display can be made completely flat, making the display suitable for touch applications. In the past, the non-flat surface of LEDs has meant that they were very hard to keep clean, or needed to have a glass overlay. That won’t be needed using COB. The displays will also be more rugged and capable of sealing for weatherproofing to IP67. The final version will be shown at Infocomm, but initially the technology will be production volume limited. “Get your orders in early”, we were told.

![]()

The firm told us that one of the challenges is to get cost down. As we highlighted in another recent Display Daily, cost at the moment is proportional to the number of pixels, so smaller displays are not cheaper and may even be more expensive at the same resolution. (http://www.displaydaily.com/article/152-display-daily/48537-what-led-has-to-do-to-be-truly-disruptive)

As well as LISA, SiliconCore had its new Quick Connect range that was shown in a 2.6mm (Peony) configuration. Quick Connect uses a a new framing system that is intended to make assembly quicker. The Quick Connect can be used in outdoor applications with different pitches and is available in 3.9mm (Tulip) with 4,500 cd/m2 of output. The tiles are 0.5m square. A front access version is available for use in fixed installations.