A team of researchers headed by Dan Luo within the Department of Electrical and Electronic Engineering at the Southern University of Science and Technology (Shenzhen, China) has developed improved Cholesteric Liquid Crystal (CLC) materials for use in electronic displays.

A recent article by the team is entitled “Full-color reflective display based on narrow bandwidth templated cholesteric liquid crystal film.” It was published in Optical Materials Express 16, Vol. 7, No. 1, 1 Jan 2017. A copy of this article is available on line and can be found here.

First, a little background information.

The molecules that compose CLCs self-arrange in a helical structure where the long axis of the molecules twist uniformly in space as a function of position along the axis of the helix. It is also possible to form such a twisted structure by dissolving a chiral (twisting) agent (molecule) into a nematic liquid crystal material.

A layer of CLC will strongly reflect light that has a wavelength half the pitch of the helical twist. In a reflective display, highly saturated colors are needed to produce a wide color gamut. Achieving a wide color gamut with CLCs requires a narrow reflection band-gap. However, in conventional CLC materials, the reflection band-gap is around 90 nm, which is too wide for practical applications. In their recent work, the researchers address this issue by the use of so-called templated CLC Films (CLCFs).

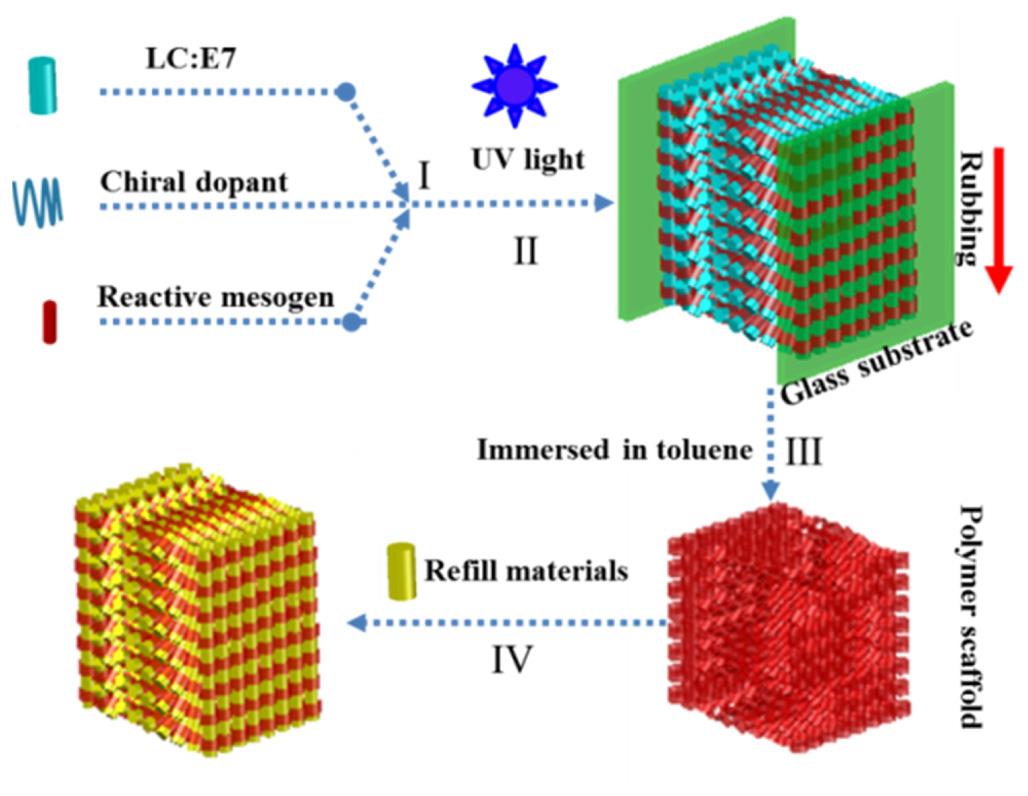

One means for creating CLCFs is by mixing CLCs in a polymer. The mixture is then exposed to UV light to induce polymerization and “freeze” the helical structure into the polymer network. The resulting film is flexible and possesses the inherent reflection characteristics of the CLC.

The reflection bandwidth of such films can be dramatically narrowed by reducing the birefringence of the film through the use of a so-called refilling process. In this process, the CLC film is soaked in toluene to remove the CLC. The vacancies thus formed in the polymer network or “scaffolding” are then refilled with molecules of a liquid crystal material that have a small birefringence. The process is illustrated in the figure below.

Fabrication of a refilled CLC film.

Fabrication of a refilled CLC film.

Using this process, the researchers found it possible to reduce the birefringence from 0.38 to 0.08. The birefringence could, in fact, be further narrowed by an additional factor of as much as two by (partially) refilling with a zero birefringence material such as toluene.

The technical article also contained a study on the effects of temperature on the properties of the films.

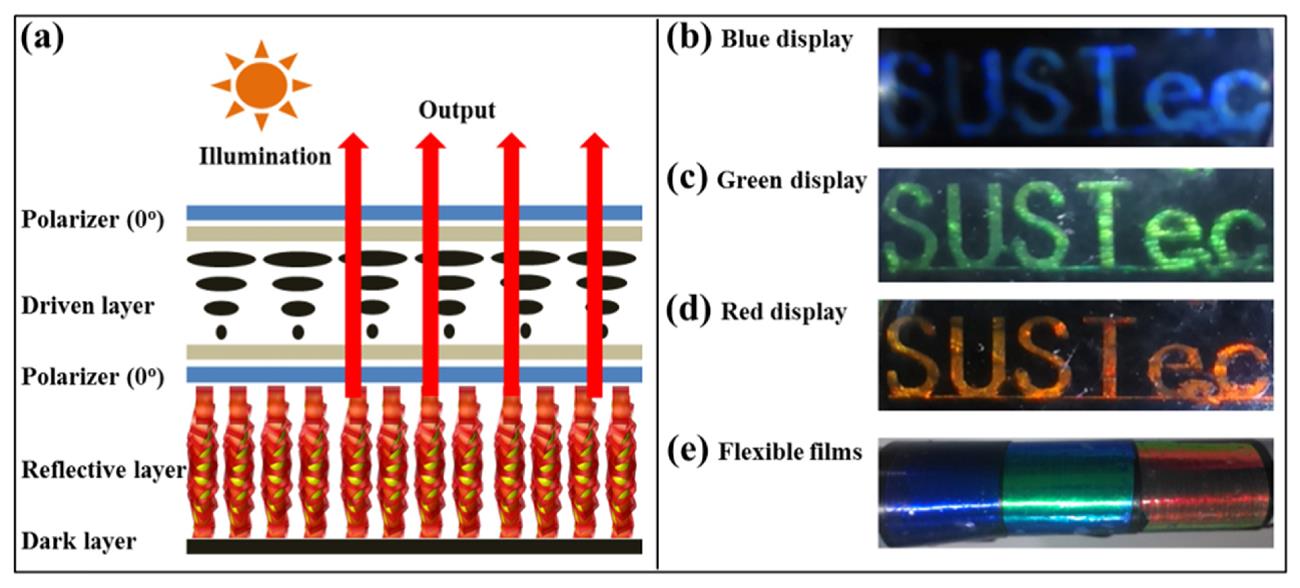

The researchers fabricated several devices to demonstrate the potential of flexible reflective films that were refilled with small birefringence liquid crystals. In doing this, the electro-optic properties of the cholesteric material were not used but, rather, just the reflective properties of the material as a passive film. Three reflective displays were fabricated. The details of the film fabrication and specifications are presented in the technical article. The figure below is a schematic diagram of the configuration and principle of operation of the reflective display.

Schematic diagram of the flexible reflective display. An electric field was applied to a red, a green and a blue film.

Schematic diagram of the flexible reflective display. An electric field was applied to a red, a green and a blue film.

The reflective devices consisted of normally black 90° twisted nematic cells with a reflective layer deposited on the bottom side of the rear polarizer. A “SUSTec” logo pattern was formed in the CLC film. A dark layer coated the bottom of the reflective layer is included to absorb all non-reflected light.

In the voltage off state, the device appeared dark. When a voltage was applied, the light passed through the bottom polarizer. In this case, the device was bright and the color reflected from the CLCF layer could be seen by a viewer.

Further studies could include forming an array of RGB films to create a full color, high reflectivity device. -Arthur Berman

Southern University of Science and Technology, Dan Luo, [email protected]