Light Polymers announces the availability of a coatable lyotropic liquid crystal material, CF001, that has flat dispersion of retardation and can be used for compensation of LCD displays.

Lyotropic liquid crystals are a unique class of materials that have the potential to revolutionize many aspects of light management in displays with better performance, simpler implementation and much lower costs.

Compensation films are typically used in LCDs to reduce the color shift that occurs when viewing the display at off angles These films can also be used in OLED displays to get a more neutral color in the off state and improve the contrast ratio, or to make both LCD and OLED displays viewable in polarized sunglasses.

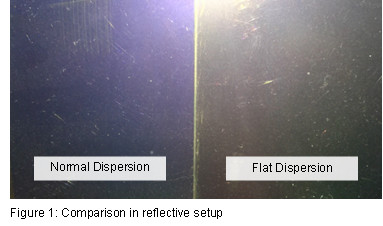

Compensation films are often characterized by their dispersion of retardation. Flat dispersion results in reduced color tint to the film when viewed from off angles. For example, many normal compensation films give a bluish tint. The compensation quality of these films is most noticeable in dark scenes or dark areas of an image. As a result, flat dispersion films with a color-neutral gray are desired (Figure 1), which the new CF001 flat dispersion material from Light Polymers provides.

This material can be coated directly on the display glass or film substrates such as TAC, COP, Polycarbonate or PMMA. Unlike other liquid crystal materials, Light Polymers’ CF001 does not need a secondary alignment process such as rubbing or photoalignment. This brings a reduction in the number of production process steps.

“What sets CF001 apart from other materials with flat dispersion, such as COP, is its ability to be coated on both plastic film substrates and glass,” noted Sergey Fedotov, Technical Product Manager. “This has the potential to simplify product manufacturing and give LCD and OLED manufacturers the opportunity to choose a film substrate or apply this material directly on-cell.”

“With current trends in LCD display industry such as super high resolutions, the display engineer faces many challenges to design thinner, brighter and more power efficient LCD and OLED displays,” noted Marc McConnaughey, President/CEO of Light Polymers, Inc. “Our materials form thin coatings on substrates or glass and bring better performance and lower costs to the display industry – and they can help enable the next generation of flexible and foldable displays.”

Light Polymers is currently qualifying coating equipment manufacturers for implementing lyotropic liquid crystal materials in production. The coating methods are slot die and microgravure for roll-to-roll coatings and slit coating for coatings on glass.

Light Polymers will be showcasing its solutions at SID DisplayWeek 2015 in San Jose from June1-5, 2015.